Manufacturing

Sheet Goods & Gaskets Materials

Discover a diverse range of rubber sheet goods suitable for industrial, construction, marine, and aerospace applications. Select from Red rubber, EPDM, Neoprene, Non-Asbestos, Natural Rubber, and Viton, available in rolls or custom-cut sheets. Our services cater to your specific requirements, including the creation of custom gaskets.

Considerations Beyond Cost: Choosing the Right Elastomer for Your Application

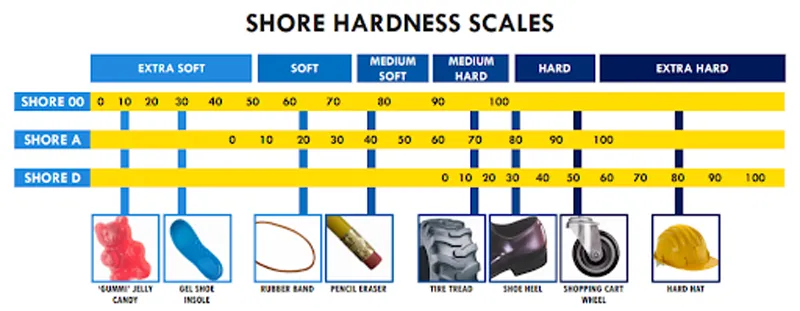

Durometer

The Durometer is the International Standard Instrument used to measure the hardness of rubber or rubber-like materials. Durometers measure hardness by the penetration of an indentor into the rubber sample. For tight fitting seals a softer durometer is recommended. However, under a heavy load, soft rubber can compress and fail. In this instance, use a higher durometer rubber sheet when it should not move as much.

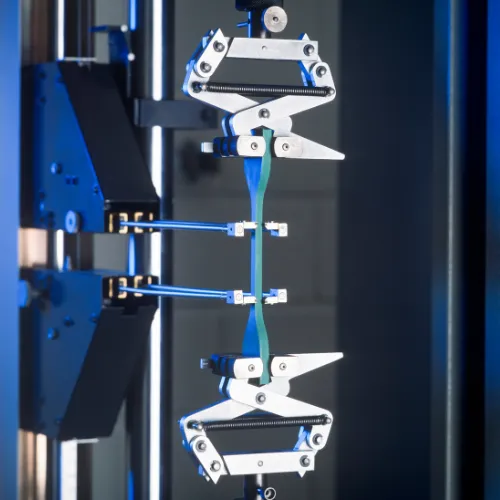

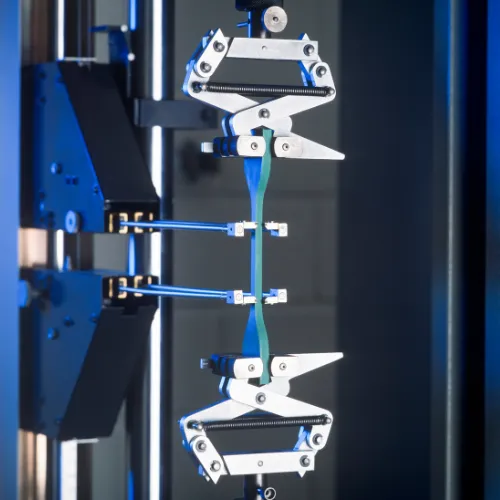

Tensile Strength

The tensile strength of rubber indicates how much force or stress a rubber material can withstand before breaking or otherwise fails. Tensile strength is often used as an important indicator regarding material quality. This is measured through the pressure unit of PSI (pounds per square inch). Abrasion, tear and impact resistance are all affected by tensile strength so it is always good to know.

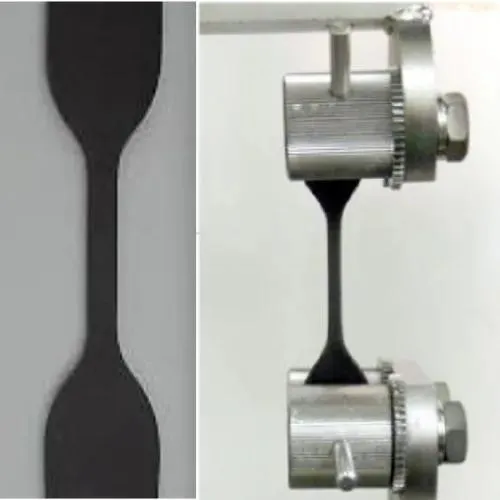

Tear Strength

Imagine a piece of rubber being pulled from opposing sides. The tear strength is how well the material holds up to the effects of tearing and if it resists nicks and cuts under tension. Tear resistance is then calculated by dividing the force applied by the thickness of the material. This is important for material in very abrasive conditions.

Compression Set

Rubber material, when compressed can lose its ability over time to return to its original thickness. In uses, such as gaskets, where they need to be reused and stressors are present, compression set is important. This refers to the ability of rubber to return to its original thickness after prolonged compressive stress at a given temperature and deflection.

Elongation

When you need material that can be stretched, bent or reshaped over and over again, you will want to take the rubber sheet elongation into account. Elongation refers to the ability of the rubber to stretch without breaking. It evaluates the maximum amount of strain a material can take before failure. It’s helpful to think of this term as “ultimate elongation” because it’s measured at the moment it tears and shown as a percent of the original length.

Explore Our Gasket Innovations

Get a leak-proof guarantee today!

Mulberry: (863) 425-4976

Orlando: (407) 634-6766

Tampa: (813) 337-6442

Miami: (305) 901-2144

© 2026 Flow Components & Industrial Supply

604 Prairie Industrial Parkway Mulberry, FL 33860