Sheet Good Materials

Thermoseal Klingersil C-4300

Thermoseal Klingersil C-4300 is a versatile, high-pressure gasket material with exceptional resistance to hot water, steam, oil, and chemicals, making it ideal for diverse applications.

This compressed fiber gasket material is manufactured with aramid fiber reinforced with a nitrile binder.

Creep relaxation ASTM F38B : 25 %

Sealability ASTM F37A (1/32″) : < 0.25 ml/hr

Gas Permeability DIN 3535/6 : < 0.5 ml/min

Compressibility ASTM F36J 7-14 % : 7 – 17 %

Recovery ASTM F36J 50% Minimum : 50 % minimum

KLINGER Hot Compression Test

Thickness Decrease 73°F (23°C) : 15 % initial

Thickness Decrease 572°F (23°C) : 25 % additional

Weight increase ASTM F146 after immersion in

Fuel B, 5h/73°F (23°C) : 10 % maximum

Thickness Increase ASTM F146 after immersion in

ASTM Oil IRM 901, 5h/300°F (149°C) : 0 – 5 %

ASTM Oil IRM 903, 5h/300°F (149°C) : 0 – 5 %

ASTM Fuel A, 5h/73°F (23°C) : 0 – 5 %

ASTM Fuel B, 5h/73°F (23°C): 0 – 10 %

Dielectric Strength ASTM D149-95a : 18 kV/mm

Density ASTM F1315 : 100 lb/ft ³ (1.6 g/cc ³)

Leachable Chloride Content FSA Method : 200 ppm

ASTM F104 Line Call Out : F712121B3E11K6M4

Color : Black or white

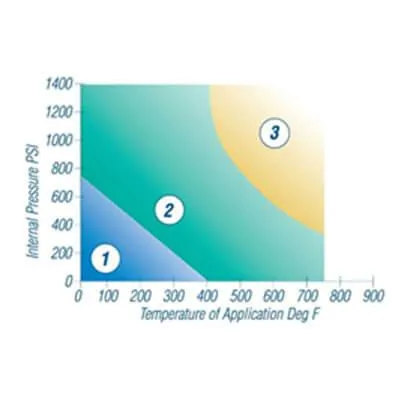

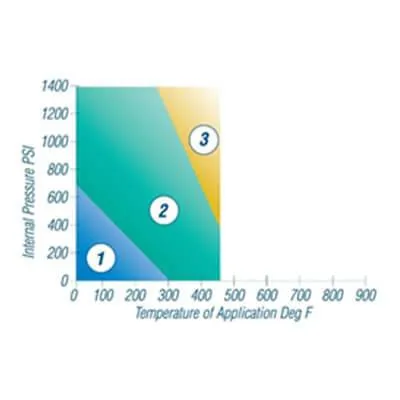

The pressure/temperature graphs shown are the most current method of determining the suitability of a gasket material in a known environment. However, chemical compatibility must also be considered.

pT diagram for thickness 1/16":

Liquids

Gases & Steam

In area 1 the gasket material is suitable using common installment practices subject to chemical compatibility

In area 2 appropriate measures are necessary for installation of the gasket to ensure maximum performance. Please call or refer to KLINGER expert for assistance.

In area 3 do not install gaskets in these applications without first referring to KLINGER expert or contacting KLINGER Thermoseal’s technical support service.

The effectiveness of a gasket in creating and sustaining a seal is influenced by factors such as the gasket material, the sealed medium, flange design, applied pressure, and the gasket assembly process. These elements, beyond the manufacturer's control, play a crucial role. Refer to our installation manual in TECHNICAL RESOURCES for detailed guidance.

Mulberry: (863) 425-4976

Orlando: (407) 634-6766

Tampa: (813) 337-6442

Miami: (305) 901-2144

© 2026 Flow Components & Industrial Supply

604 Prairie Industrial Parkway Mulberry, FL 33860